This Enclosure Solutions Wall System includes a CMU structure with masonry veneer and mineral wool continuous insulation with fluid or sheet applied air and water resistive barrier (AWB). Complies with NFPA 285(fire), ASTM E2357 (air) and ASTM E331 (water).

Get all the construction documentation you'll need, in a single click:

Sold Separately

Durability

Durability Easy Installation

Easy Installation Fire Resistance

Fire Resistance Thermal Comfort

Thermal Comfort

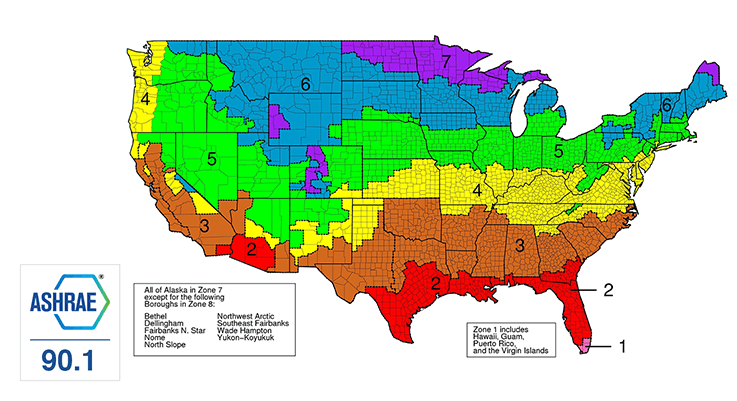

ASHRAE Standard 90.1 requires Continuous Insulation (CI) be used for all commercial and some residential buildings in the United States. Continuous insulation is defined in 90.1 as “insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope”.

Learn More

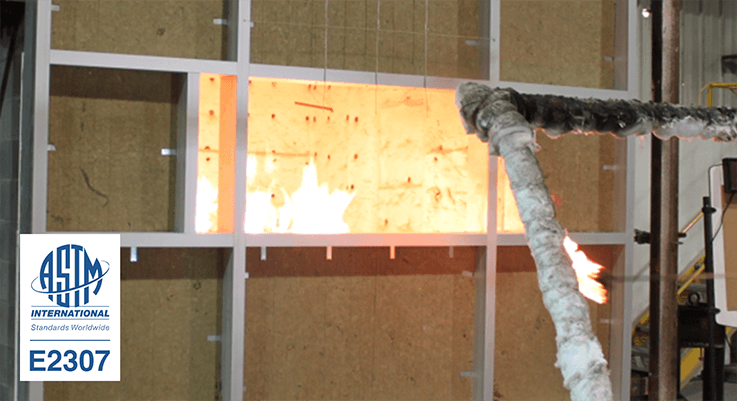

ASTM E2307 measures the ability of perimeter fire barrier systems to maintain a seal and prevent interior fire spread as the exterior wall assembly deflects and deforms during fire exposure. The ASTM E2307 test exposes the joint to fire from the room of fire origin and the exterior wall to fire from both the interior and the exterior as the fire plume exits the room of fire origin through a window opening. ASTM E 2307 determines the period of time that the perimeter fire containment system will limit flame penetration through the opening between the exterior wall assembly and the floor assembly.

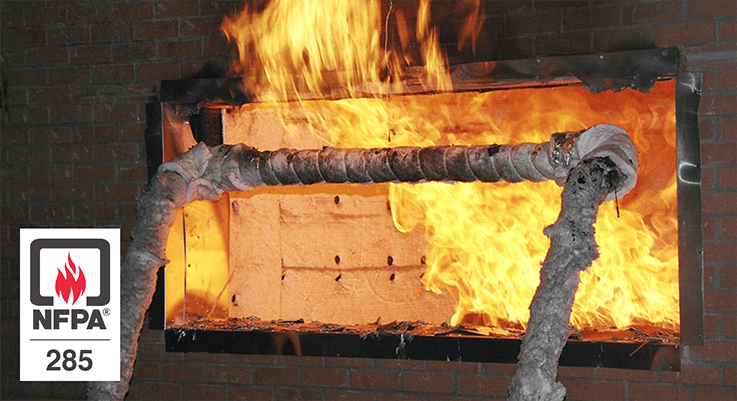

NFPA 285 is required in the International Building Code (IBC) in multiple situations. The NFPA 285 test is to determine that combustibles, when exposed to fire on the exterior face of the wall, do not spread flame over the surface or through the core of the otherwise non-combustible wall assembly.

Learn more at NFPA.orgThis wall assembly enclosure also meets the following codes and standards. Click a standard to learn more

Construction Details including CAD drawing files for CMU Enclosure Solutions Wall Systems are available for download below.

with Masonry Return and Wash Cavity Closure

with FRTW Blocking Cavity Closure

with Thermafiber Safing Cavity

with Thermafiber and Loose Angle Cavity Closure

with Steel Angle Cavity Closure

Owens Corning® Enclosure Solutions deliver buildings that perform without compromising design. Take a look at a few key case studies below.

The time consuming work of researching and specifying individual products is completed for you and delivered with fully detailed documentation, for more efficient and accurate bidding and planning. Get all the construction documents you need in a single click:

Even though we’re a global company, we’re always ready to answer your questions. Call to speak with an Owens Corning representative so you can start your project right away.

1-800-GET-PINK®